Mainsails fed into grooves - typically racing yachts From 60 footers, One Design classes to small dinghys - will eventually experience an unavoidable chafe to the luff tape that connect the mainsail with the mast, ultimately resulting in breakdown and hence the sail won't hoist.

Especially the many carbon spars at the scene these days are chewing up tapes like alligators...

Especially the many carbon spars at the scene these days are chewing up tapes like alligators...

Problem gone

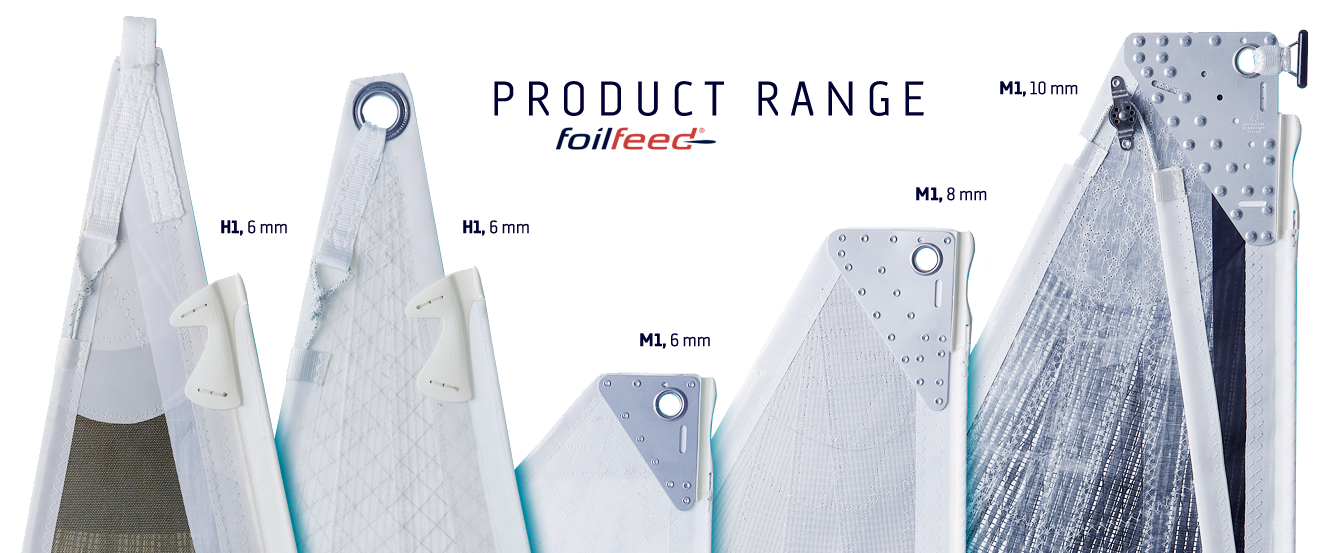

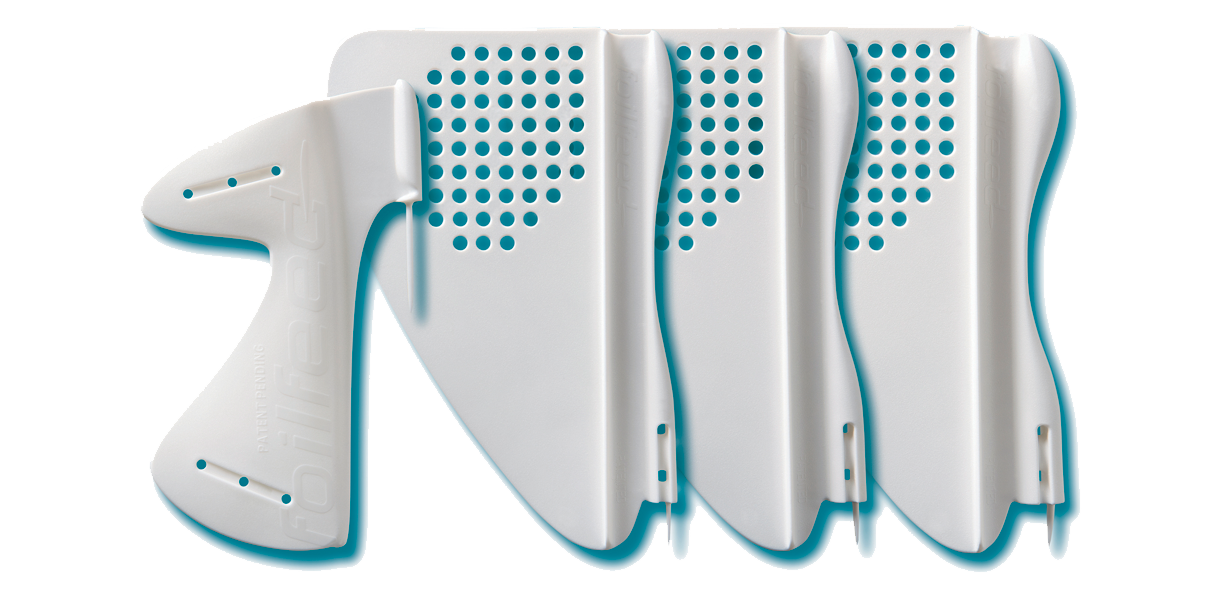

The Foilfeed® M1 puts an end to this problem once and for all, by both capping the end of the luff tape, shielding the mast from a chafing headboard and hence adding protection, strength and reliability to a fragile part of the mainsail.

The unique and patented design represent a solution to what has been a continous weakness of sails being hoisted in grooves for more than four decades.

Get the Foilfeed® M1 Brochure here >

The unique and patented design represent a solution to what has been a continous weakness of sails being hoisted in grooves for more than four decades.

Get the Foilfeed® M1 Brochure here >

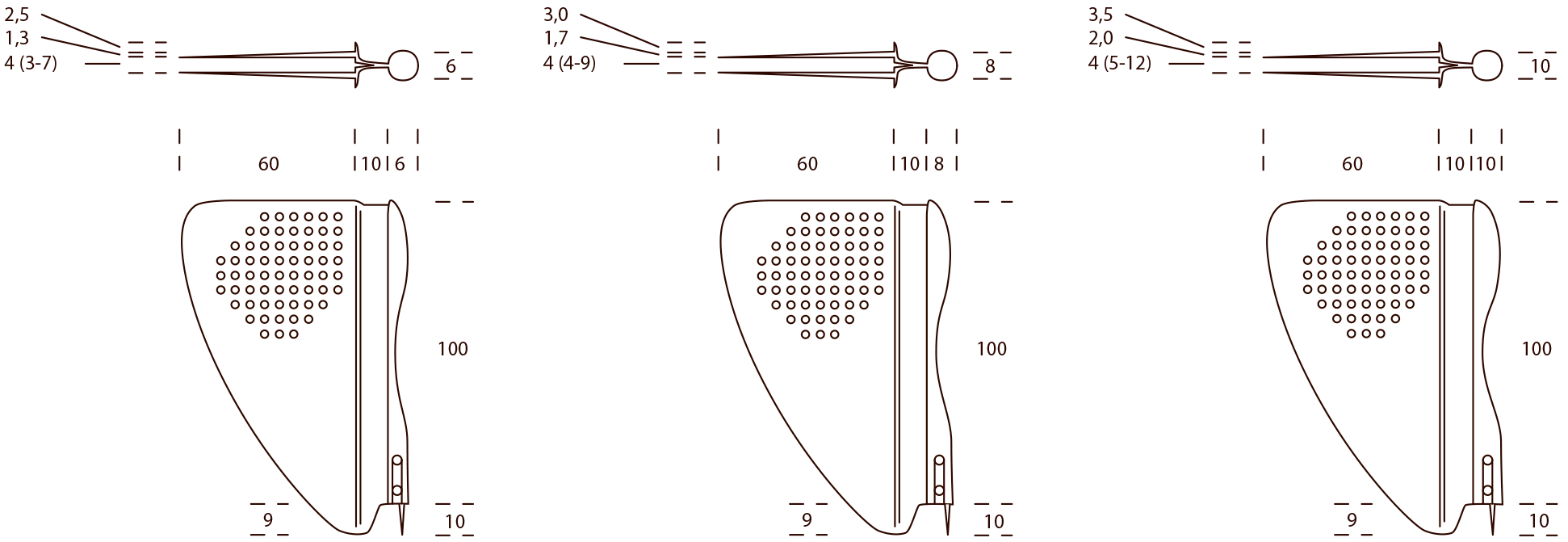

3 sizes match standards

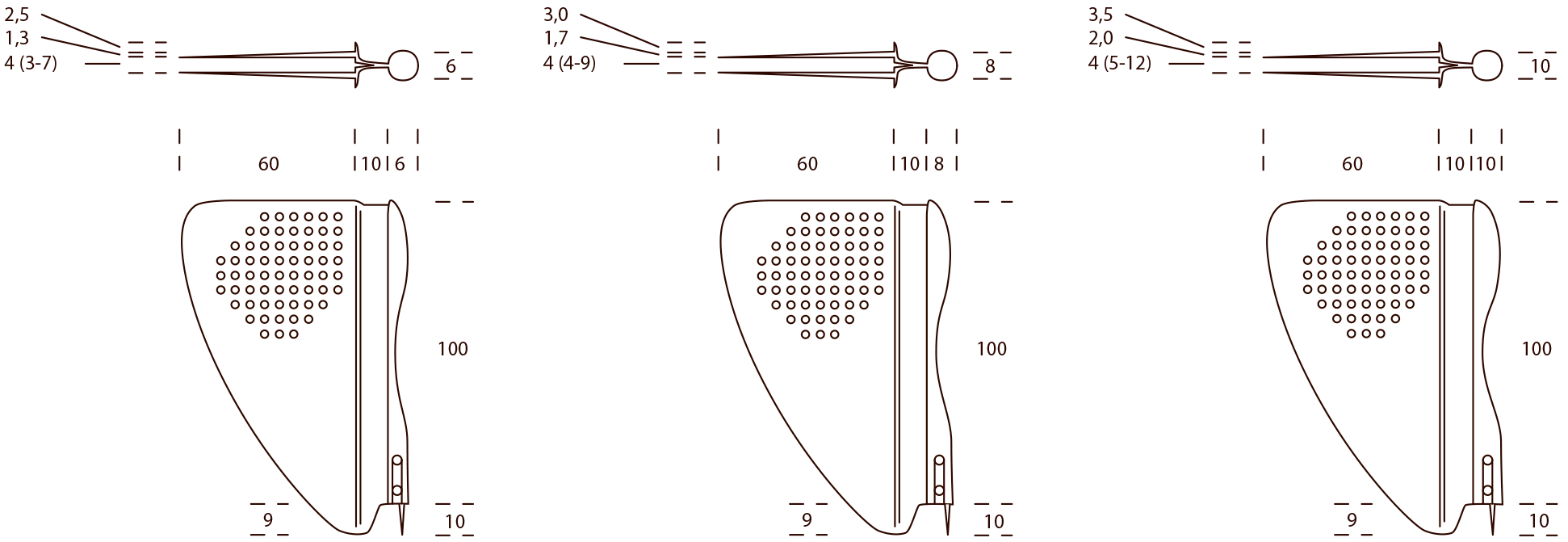

The sailmaking operate with three bolt rope diameters: 6 mm, 8 mm and 10 mm. The predominant size is the 8 mm, but Foilfeed® M1 come in all 3 sizes to accomodate industry needs.

TP52's use 8 mm bolt rope and DN Ice boats use 10 mm. The logic behind prevailing dimensions in various classes is more about existing groove standards from spars than actual loads and dimensioning hereby.

Bolt rope cores come in various qualities as well, whereas traditional rope is made of actual rope other may by a solid core of some plastic.

Foilfeed® M1 work on both qualities of cores and all 3 dimensions.

TP52's use 8 mm bolt rope and DN Ice boats use 10 mm. The logic behind prevailing dimensions in various classes is more about existing groove standards from spars than actual loads and dimensioning hereby.

Bolt rope cores come in various qualities as well, whereas traditional rope is made of actual rope other may by a solid core of some plastic.

Foilfeed® M1 work on both qualities of cores and all 3 dimensions.

NO HEADBOARD FOR DINGHIES

The M1 model have turned out - in practise - to be great head support for mainsails on small dinghies like Snipe, 470, Europe, OK, Finn, Tornado, 29er, 49er that do not need the heavy solution with a riveted headboard.

The head will just consist of thick stiff layers of cloth, the Foilfeed® M1 and the ring/ web for attaching the halyard.

This solution is not just radical a weightsaver for the whole head itself (which is quite favorable), but also an improvement in the production process for the sailmaker, since it does not require heavy sewing, but can be done on one single machine.

Get your Installing Manual here >

The head will just consist of thick stiff layers of cloth, the Foilfeed® M1 and the ring/ web for attaching the halyard.

This solution is not just radical a weightsaver for the whole head itself (which is quite favorable), but also an improvement in the production process for the sailmaker, since it does not require heavy sewing, but can be done on one single machine.

Get your Installing Manual here >

Carbon damager

Traditionally luff tapes on mainsails have been fed in Alloy grooves, but with the immense spread of carbon spars these days the chafe problems have increased drastically.

The cause is simple; Carbon spars are woven threads and epoxy varnished for smoothness. But varnish will be sanded off quickly by the luff tape and then you have direct contact - carbon weave to dacron weave (luff tape). The carbon fibers are simply eating up dacron like putting a knife in butter.

Especially skiffs experience these problems with the large heads and roaches.

The cause is simple; Carbon spars are woven threads and epoxy varnished for smoothness. But varnish will be sanded off quickly by the luff tape and then you have direct contact - carbon weave to dacron weave (luff tape). The carbon fibers are simply eating up dacron like putting a knife in butter.

Especially skiffs experience these problems with the large heads and roaches.

You may have an older sail with a traditional riveted headboard and you're sick and tired of luff tape debacles; No sweat. Take your sail to your sailmaker and make a retrofit.

It is not a large operation, but it requires a sailmakers special tools, not carried in a simple pouch or tool box.

Talk to your sailmaker about it and remember to order your new sail with a Foilfeed® M1 mounted from the start.

Get your Installing Manual here >

It is not a large operation, but it requires a sailmakers special tools, not carried in a simple pouch or tool box.

Talk to your sailmaker about it and remember to order your new sail with a Foilfeed® M1 mounted from the start.

Get your Installing Manual here >

Whether you buy on retail or wholesale terms, all purchases are done via the online shop and delivered worldwide. If you are a sailmaker, sign up >and get wholesale privileges by including you Tax ID etc. All payments are done by credit card. Go to the Foilfeed® online shop here >

Go to the Foilfeed® online shop here >

Go to the Foilfeed® online shop here >

Go to the Foilfeed® online shop here >Material

The Foilfeed® M1 is made of Delrin® POM due to its strength, durability and its non-friction properties.

The homopolymer grades (Technical name for Delrin®) have a higher mechanical strength, stiffness, hardness and creep resistance as well as a lower thermal expansion rate and often it also presents a better wear resistance.

Delrin® is designed for applications requiring low wear and/or low friction against steel, itself and other plastics. Delrin® POM is used in many static and dynamic industrial applications replacing materials like steel brass, bronze, copper & aluminum. Polyacetal have improved part life because of better wear, more chemical, corrosion and UV-resistance. These materials reduce noise and will reduce or eliminate the need for lubricants. Delrin® POM can be used in applications such as Gears, Bushings, Bearings, Rollers, Timing Screws, Manifolds, Valves & Valve bodies, Washers, Wear pads and many industrial machine parts.

Main Characteristics of Delrin® POM:

• High mechanical strength, stiffness, hardness and toughness • Excellent resilience • Good creep resistance • High impact strength, even at low temperatures • Very good dimensional stability • Good sliding properties and wear resistance • UV-resistant

The homopolymer grades (Technical name for Delrin®) have a higher mechanical strength, stiffness, hardness and creep resistance as well as a lower thermal expansion rate and often it also presents a better wear resistance.

Delrin® is designed for applications requiring low wear and/or low friction against steel, itself and other plastics. Delrin® POM is used in many static and dynamic industrial applications replacing materials like steel brass, bronze, copper & aluminum. Polyacetal have improved part life because of better wear, more chemical, corrosion and UV-resistance. These materials reduce noise and will reduce or eliminate the need for lubricants. Delrin® POM can be used in applications such as Gears, Bushings, Bearings, Rollers, Timing Screws, Manifolds, Valves & Valve bodies, Washers, Wear pads and many industrial machine parts.

Main Characteristics of Delrin® POM:

• High mechanical strength, stiffness, hardness and toughness • Excellent resilience • Good creep resistance • High impact strength, even at low temperatures • Very good dimensional stability • Good sliding properties and wear resistance • UV-resistant

Geometry and design

The Foilfeed® M1 is designed to solve the old problem with chafing luff tape, improving functionality and at the same time building in some features not found in the existing solutions, saving the sailmakers 3-5 handwork routines at the same time.

The 3 variants - made for rope thicknesses 8 mm, 10 mm and 12 mm - is also expandable at the surfaces underneath the headboard plates, enabling various dimensions of reinforcements to fit inside as desired.

Whatever M1 variant you may choose, the cutout dimension is the same (10 by 100 mm), so that sailmakers easily can remember dimensions.

The 10 mm version weighs just about 10 grams making it the lightest solution possible. The height of the mastcovers keeps headboards of 3 mm thicknes clear of masts and due to the material Delrin® POM, friction is kept at the lowest level.

The 3 variants - made for rope thicknesses 8 mm, 10 mm and 12 mm - is also expandable at the surfaces underneath the headboard plates, enabling various dimensions of reinforcements to fit inside as desired.

Whatever M1 variant you may choose, the cutout dimension is the same (10 by 100 mm), so that sailmakers easily can remember dimensions.

The 10 mm version weighs just about 10 grams making it the lightest solution possible. The height of the mastcovers keeps headboards of 3 mm thicknes clear of masts and due to the material Delrin® POM, friction is kept at the lowest level.

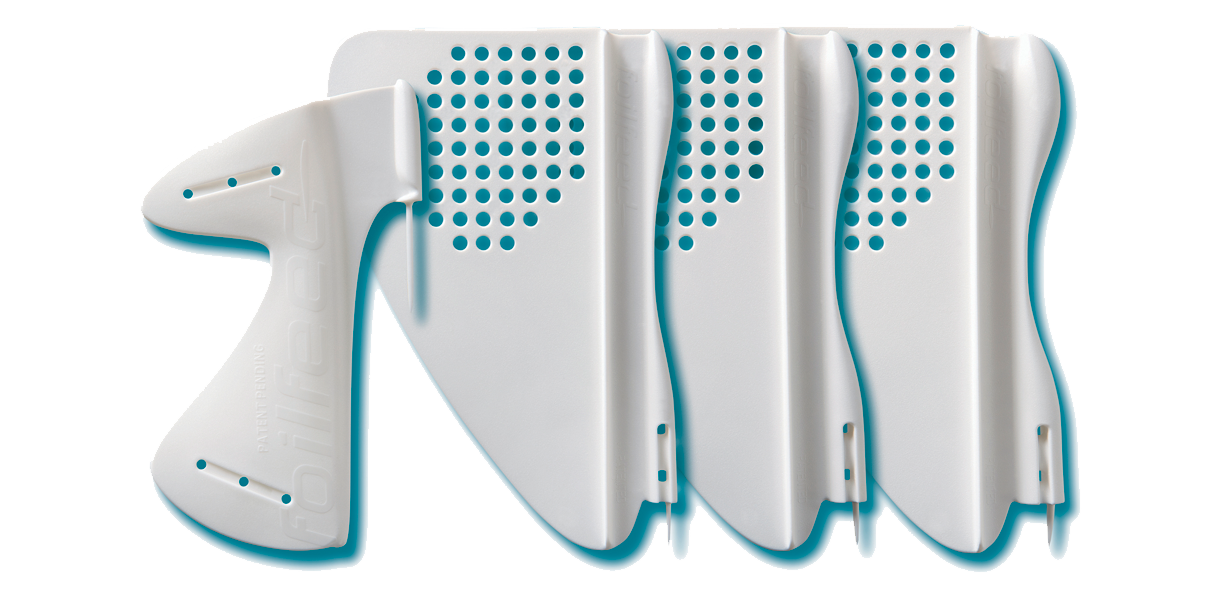

Color and UV-resistance

The Foilfeed® M1 is made of bright white Delrin POM. There are two main reasons for that:

1. Aethstaetics:

Since all standard fittings, tapes and other nylon additions to a sail is white, the Foilfeed® M1 will fit in the general looks and design from all major sailmakers worldwide.

2. UV-resistance:

The color white is best to reflect the UV from the sun and furthermore, the Delrin® POM has been mixed with 2% UV-block in the moulding process making it more resistant to UV radiation, hence less degradable than most plastic products over time.

1. Aethstaetics:

Since all standard fittings, tapes and other nylon additions to a sail is white, the Foilfeed® M1 will fit in the general looks and design from all major sailmakers worldwide.

2. UV-resistance:

The color white is best to reflect the UV from the sun and furthermore, the Delrin® POM has been mixed with 2% UV-block in the moulding process making it more resistant to UV radiation, hence less degradable than most plastic products over time.

Liabilty

Foilfeed® M1 is made only for use on sails installed with luff tapes to be hoisted into grooves on sailing yachts. Any other use of Foilfeed® M1 will void both the warranty, reponsibility and liability. Foilfeed® cannot be held accountable for any actions from its customers or the consequences from these, while using the Foilfeed®.

Keep Foilfeed® away from infants and kids below 8 years of age.

Keep Foilfeed® away from infants and kids below 8 years of age.