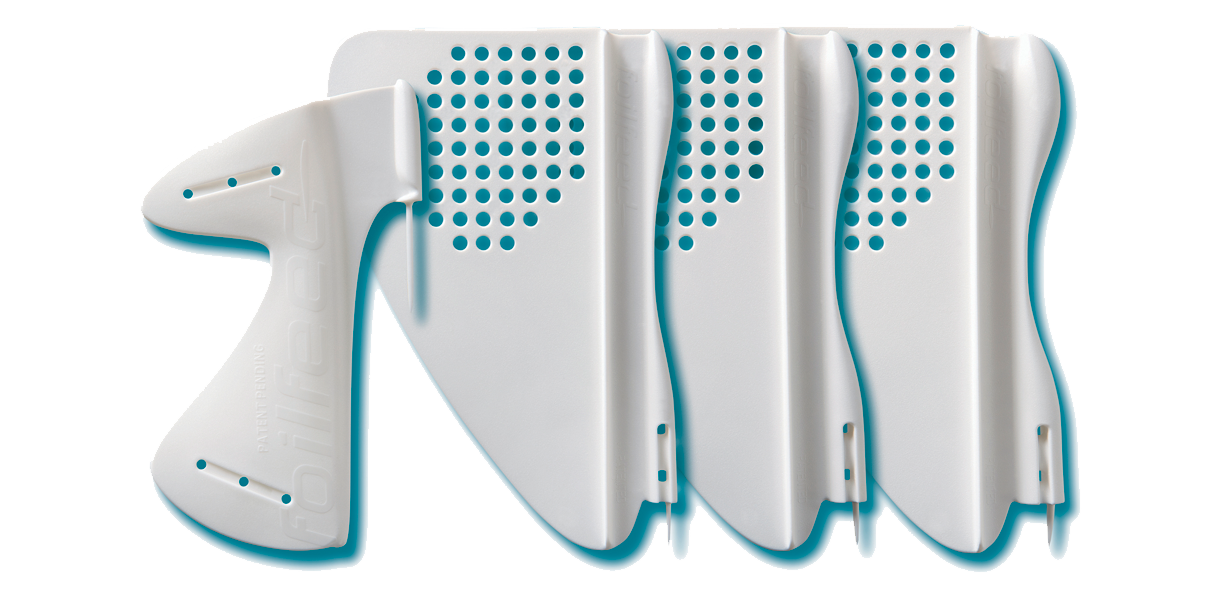

Headsails fed into grooves -racing or cruising - will eventually experience an unavoidable chafe

to the luff tape that connect the headsail with the forestay, ultimately resulting in breakdown and hence the sail won't hoist. With Foilfeed® H1; Just 100% reliable hoists and no more repairs!

to the luff tape that connect the headsail with the forestay, ultimately resulting in breakdown and hence the sail won't hoist. With Foilfeed® H1; Just 100% reliable hoists and no more repairs!

Problem gone

The Foilfeed® H1 puts an end to this problem once and for all by capping the end of the luff tape hence adding protection, strength and reliability to a fragile part of a sail.

The unique and patented design represents a solution to what has been a continous weakness of sails being hoisted in grooves for almost four decades.

Now, that problem is over...

The unique and patented design represents a solution to what has been a continous weakness of sails being hoisted in grooves for almost four decades.

Now, that problem is over...

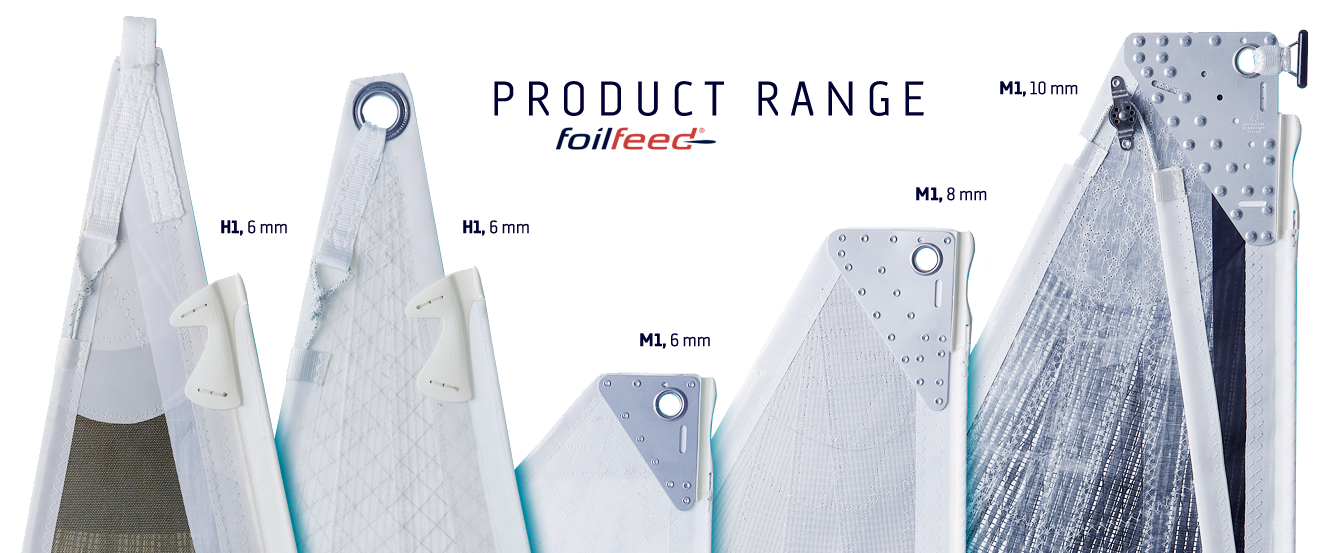

1 size match 6 mm

The sailmaking operate with three bolt rope diameters: 6 mm, 8 mm and 10 mm. The predominant size is the 8 mm, but Foilfeed® M1 come in all 3 sizes to accomodate industry needs.

TP52's use 8 mm bolt rope and DN Ice boats use 10 mm. The logic behind prevailing dimensions in various classes is more about existing groove standards from spars than actual loads and dimensioning hereby.

Bolt rope cores come in various qualities as well, whereas traditional rope is made of actual rope other may by a solid core of some plastic.

Foilfeed® M1 work on both qualities of cores and all 3 dimensions.

Download the Brochure >

TP52's use 8 mm bolt rope and DN Ice boats use 10 mm. The logic behind prevailing dimensions in various classes is more about existing groove standards from spars than actual loads and dimensioning hereby.

Bolt rope cores come in various qualities as well, whereas traditional rope is made of actual rope other may by a solid core of some plastic.

Foilfeed® M1 work on both qualities of cores and all 3 dimensions.

Download the Brochure >

install on site

The M1 model have turned out - in practise - to be great head support for mainsails on small dinghies like Snipe, 470, Europe, OK, Finn, Tornado, 29er, 49er that do not need the heavy solution with a riveted headboard.

The head will just consist of thick stiff layers of cloth, the Foilfeed® M1 and the ring/ web for attaching the halyard.

This solution is not just radical a weightsaver for the whole head itself (which is quite favorable), but also an improvement in the production process for the sailmaker, since it does not require heavy sewing, but can be done on one single machine.

Get Installation Manual Here >

The head will just consist of thick stiff layers of cloth, the Foilfeed® M1 and the ring/ web for attaching the halyard.

This solution is not just radical a weightsaver for the whole head itself (which is quite favorable), but also an improvement in the production process for the sailmaker, since it does not require heavy sewing, but can be done on one single machine.

Get Installation Manual Here >

Easier handling

You know the feeling; Cold, soaked, stressed and on a tight schedule before the bottom mark.

The last thing you need is having a bunch of wise guys in the back yelling at ya' while trying to get the remaining fray up the the pre-feeder just to meet the very narrow opening of a feeder before actually being able to give 'thumbs up' to the back before hoisting the headsail.

The last thing you need is having a bunch of wise guys in the back yelling at ya' while trying to get the remaining fray up the the pre-feeder just to meet the very narrow opening of a feeder before actually being able to give 'thumbs up' to the back before hoisting the headsail.

All that is just gone with a Foilfeed® H1, since it is a hard-shelled and therefore can be fed as easy and fast as drawing a six-shooter.

When a bowman is happy; It runs down to the back and everybody's happy!

Perfect for Retrofit

You are probably having a headsail that were not delivered with a Foilfeed® fitted on to the head.

No problem; You can install within 5 minutes on spot if you have a drill, needle, thread and can stick.

Please read Installation Manual Here > carefully before performing. And do not install if your luff tape is born with an Ease-out-solution > due to geometrical misfit.

Get Installation Manual Here >

No problem; You can install within 5 minutes on spot if you have a drill, needle, thread and can stick.

Please read Installation Manual Here > carefully before performing. And do not install if your luff tape is born with an Ease-out-solution > due to geometrical misfit.

Get Installation Manual Here >

Whether you buy on retail or wholesale terms, all purchases are done via the online shop and delivered worldwide. If you are a sailmaker, sign up >and get wholesale privileges by including you Tax ID etc. All payments are done by credit card. Go to the Foilfeed® Online Shop here >

Go to the Foilfeed® Online Shop here >

Go to the Foilfeed® Online Shop here >

Go to the Foilfeed® Online Shop here >Key features

• Protects Luff Tapes when inserted and functioning in grooves

• 100% hoisting and feeding reliability

• Quality improvement compared to all existing sailmaking standards

• Mounting by simple sticthing. No permanent damage to sail

• Save time and money mounting Foilfeed® to your customers sails

• No ease-out solutions needed

• Easier, safer and faster handling for bowmen

• H1 come in 1 size: For 6 mm rope (single and double)

• Made in white Delrin POM, UV protected solution added

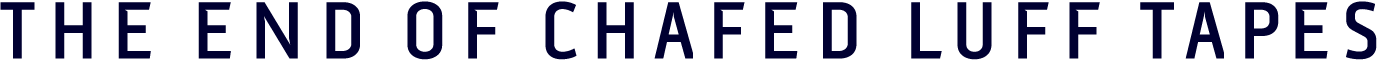

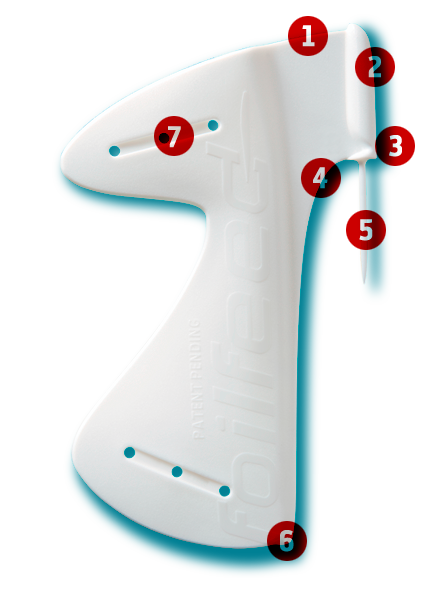

Diagram of H1

1. The feeding fin

This part is the part replaces the weakest part of the luff tape - the edge. Thanks to the durability of the material, this part can be fed on and on and on...

2. The 'projectile'

Will be the connector part inside the groove, shaped in order to keep feeding as easy and quick as possible

3. Back- and forth feeding feature

Extrusions shorter than the actual luff tape luff will experience a feed back-into-groove-motion, when lowering the sail. The foilfeed® H1 takes care of that

4. Front slit

Dividing the Foilfeed® H1 so the luff tape can be placed inside for protection

5. The Spike

This part is to be lowered into the center of the rope in order to align perfectly

6. Cover surface for luff tape

When foilfeed® H1 is being lowered onto the luff tape, the top edge will be covered, aligned and protected between the two surfaces

7. Groove for stitch protection

Stitches are lowered avoiding tear and wear compromising the fixture

Material

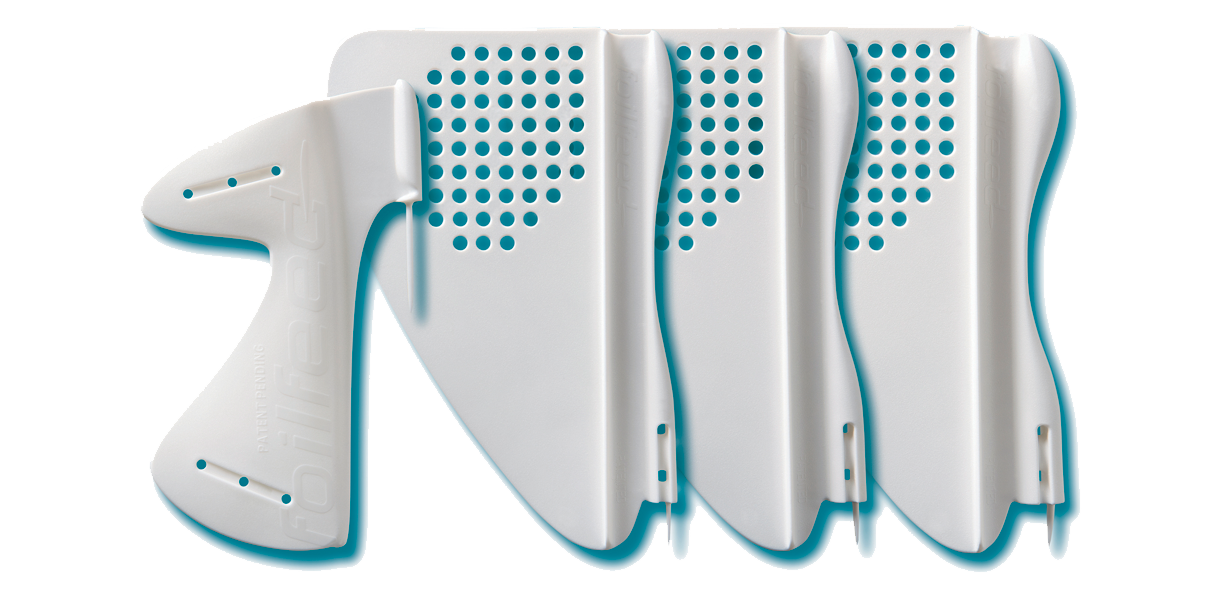

The Foilfeed® H1 is made of Delrin® POM due to its strength, durability and its non-friction properties.

The homopolymer grades (Technical name for Delrin®) have a higher mechanical strength, stiffness, hardness and creep resistance as well as a lower thermal expansion rate and often it also presents a better wear resistance.

Delrin® is designed for applications requiring low wear and/or low friction against steel, itself and other plastics. Delrin® POM is used in many static and dynamic industrial applications replacing materials like steel brass, bronze, copper & aluminum. Polyacetal have improved part life because of better wear, more chemical, corrosion and UV-resistance. These materials reduce noise and will reduce or eliminate the need for lubricants. Delrin® POM can be used in applications such as Gears, Bushings, Bearings, Rollers, Timing Screws, Manifolds, Valves & Valve bodies, Washers, Wear pads and many industrial machine parts.

Main Characteristics of Delrin® POM:

• High mechanical strength, stiffness, hardness and toughness • Excellent resilience • Good creep resistance • High impact strength, even at low temperatures • Very good dimensional stability • Good sliding properties and wear resistance • UV-resistant

The homopolymer grades (Technical name for Delrin®) have a higher mechanical strength, stiffness, hardness and creep resistance as well as a lower thermal expansion rate and often it also presents a better wear resistance.

Delrin® is designed for applications requiring low wear and/or low friction against steel, itself and other plastics. Delrin® POM is used in many static and dynamic industrial applications replacing materials like steel brass, bronze, copper & aluminum. Polyacetal have improved part life because of better wear, more chemical, corrosion and UV-resistance. These materials reduce noise and will reduce or eliminate the need for lubricants. Delrin® POM can be used in applications such as Gears, Bushings, Bearings, Rollers, Timing Screws, Manifolds, Valves & Valve bodies, Washers, Wear pads and many industrial machine parts.

Main Characteristics of Delrin® POM:

• High mechanical strength, stiffness, hardness and toughness • Excellent resilience • Good creep resistance • High impact strength, even at low temperatures • Very good dimensional stability • Good sliding properties and wear resistance • UV-resistant

Geometry and design

The Foilfeed® H1 is designed to meet the geometrical requirements of all major suppliers of headsail furlings systems, foil extrusions and grooves, including feeders.

Though the H1 is primarily made for 6 mm ropes, it has also proven usable on 5 mm and 7 mm ropes too, though it depends entirely on the actual setup.

The 'projectile' (item advanced into groove) is designed to be inserted both forth and back, meaning that a fully hoisted sail on too short an extrusion, will be able to feed back when lowering the sail again. The spike (pin lowered into the rope) cannot break by either stepping on or by normal handling. It will only bend sideways.

Since it is 20 mm long it will not be able to 'jump' out of position unless the whole area is being ripped apart.

Attaching Foilfeed® H1 to the sail is done by hand stitching. When tightening and securing the thread the sticthing will be lowered into the built-in grooves protecting it from tear and wear of general sail handling.

The Foilfeed® H1 weighs 19 grams.

Though the H1 is primarily made for 6 mm ropes, it has also proven usable on 5 mm and 7 mm ropes too, though it depends entirely on the actual setup.

The 'projectile' (item advanced into groove) is designed to be inserted both forth and back, meaning that a fully hoisted sail on too short an extrusion, will be able to feed back when lowering the sail again. The spike (pin lowered into the rope) cannot break by either stepping on or by normal handling. It will only bend sideways.

Since it is 20 mm long it will not be able to 'jump' out of position unless the whole area is being ripped apart.

Attaching Foilfeed® H1 to the sail is done by hand stitching. When tightening and securing the thread the sticthing will be lowered into the built-in grooves protecting it from tear and wear of general sail handling.

The Foilfeed® H1 weighs 19 grams.

Color and UV-resistance

The Foilfeed® M1 is made of bright white Delrin POM. There are two main reasons for that:

1. Aethstaetics:

Since all standard fittings, tapes and other nylon additions to a sail is white, the Foilfeed® M1 will fit in the general looks and design from all major sailmakers worldwide.

2. UV-resistance:

The color white is best to reflect the UV from the sun and furthermore, the Delrin® POM has been mixed with 2% UV-block in the moulding process making it more resistant to UV radiation, hence less degradable than most plastic products over time.

1. Aethstaetics:

Since all standard fittings, tapes and other nylon additions to a sail is white, the Foilfeed® M1 will fit in the general looks and design from all major sailmakers worldwide.

2. UV-resistance:

The color white is best to reflect the UV from the sun and furthermore, the Delrin® POM has been mixed with 2% UV-block in the moulding process making it more resistant to UV radiation, hence less degradable than most plastic products over time.

Liabilty

Foilfeed® M1 is made only for use on sails installed with luff tapes to be hoisted into grooves on sailing yachts. Any other use of Foilfeed® M1 will void both the warranty, reponsibility and liability. Foilfeed® cannot be held accountable for any actions from its customers or the consequences from these, while using the Foilfeed®.

Keep Foilfeed® away from infants and kids below 8 years of age.

Keep Foilfeed® away from infants and kids below 8 years of age.